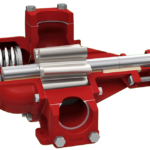

Unveiled at ACHEMA 2015, these new Abaque models incorporate a stronger and durable rotor design and innovative hose holding system while featuring a fresh, new look of orange and black.

Abaque pumps meet the challenging requirements of the chemicals industry, thanks in part to its seal-free design that eliminates leaks and product contamination. These self-priming pumps can run in forward or reverse and offer suction-lift capabilities to 25.5 feet (9 meters), as well as the ability to run dry without adversely affecting performance, pressure and accuracy (no slip). Abaque pumps are available in ductile iron and stainless steel construction, allowing higher discharge pressure up to 217 psi (15 bar).

“As one of the world’s largest trade shows dedicated to the chemical-processing industry, the ACHEMA Show was a perfect venue to debut new models of, as

well as the new look for, the Abaque Series pumps,” said Christophe Jovani, PSG EMEA Marketing Communications Manager. “Achieving full containment of raw materials, many of which can be hazardous to people and the environment, is a key consideration for chemical processors. Abaque pumps are the ideal technology to utilize when looking to optimize the safe and efficient handling and transfer of these dangerous chemical materials.”

Additionally, Mouvex is pleased to announce that is celebrating its 50th anniversary of manufacturing A Series pumps in 2015. Since 1965, A Series pumps have been manufactured, assembled and shipped from the PSG® Auxerre, France facility. Known for their reliability, durability and cost effectiveness, A Series pumps have earned a reputation as the ideal pumping technology for some of the harshest applications in the world.

Additionally, Mouvex is pleased to announce that is celebrating its 50th anniversary of manufacturing A Series pumps in 2015. Since 1965, A Series pumps have been manufactured, assembled and shipped from the PSG® Auxerre, France facility. Known for their reliability, durability and cost effectiveness, A Series pumps have earned a reputation as the ideal pumping technology for some of the harshest applications in the world.